What is a single lumen catheter?

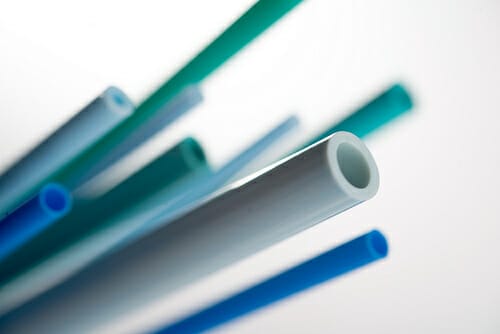

Lumens are the inner spaces in tubes that transport liquids, gases or surgical devices during a medical procedure. There can be a single lumen device or multiple lumens, and the configurations and numbers are almost limitless. When a catheter has a single hole through the center of it, it is referred to as a single lumen. Single lumens are most commonly used in IV, urological and drainage catheters.

What options are available from Putnam Plastics for a single lumen tube?

Putnam gives you an extensive range of options for your single lumen extrusion:

- choice of color

- broad selection of shapes

- comprehensive range of thermoplastic material

- sizes from .010” (0.254 mm) to 1” (25.4 mm)

What materials does Putnam offer for single lumen tube extrusion?

Single lumen tubes can be made from almost any thermoplastic material, including but not limited to:

- Pebax

- Nylon

- Polyethylene

- Polyurethane

- Polyester

- PEEK

- Polyimide

- Polypropylene

- C-flex

- PFA (Perfluoroalkoxy)

- FEP (Fluorinated ethylene propylene)

What medical devices are single channel tubes commonly used in?

Single lumen configurations are used for a wide variety of medical applications such as intravenous lines (IV) and drainage or urological catheters.

What ISO certifications is Putnam Plastics equipped to comply with?

Putnam’s premier custom tubing manufacturing facility is ISO 13485:2016 certified. Our ISO compliant clean room meets the growing demand for greater regulatory controls of extrusions and finishing components of medical devices.

Why is Putnam Plastics the best choice for this product?

Putnam Plastics has been producing medical extrusions for over 40 years. You will have the widest range of polymers, in the widest range of sizes, to chose from.

Our custom components unit focuses on post-processing steps such as forming catheter ends and attaching insert molding hubs and connectors—all in-house. This not only increases speed to market but also provides cost savings for you.